FAQs

-

What is a Tapered Thread?

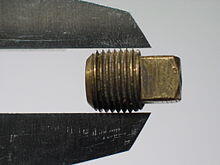

Threaded pipe fittings for use in installations for the delivery of air, gases or fluids under pressure have a threaded section that is slightly conical (in contrast to the cylindrical section commonly found on bolts and leadscrews). This is called a "tapered thread". The seal attained within a threaded pipe joint depends upon the seal created by the deformation of the threads when they are tightened to the proper torque and, in almost all applications, the use of a sealing coating such as thread seal tape ("Teflon tape"), a liquid or paste pipe sealant such as pipe dope, or pre-applied sealant. Tapered thread joints typically do not include a gasket.

"Visual" of a Tapered Thread pipe plug; note that the threaded portion is tapered and so touches the calipers at only two points. Photo by Ben Frantz Dale

-

What are "NPT" Threads?

"NPT" (National Pipe Thread/Tapered) designates the thread form often used for standard commercial "U.S. inch" pipe and pipe fittings. The NPT thread form is designed for flank-to-flank interference fit and requires use of some type of sealing material applied to the threads to achieve adequate seal.

-

What are "NPTF" Threads?

"NPTF" (National Pipe Thread Fuel-Tapered) designates the thread form most commonly found on "U.S. inch" pipe plugs. The NPTF thread form is designed for crest-to-root contact. These "crush" immediately prior to the mating thread flanks making contact, to achieve maximum metal to metal interference fit. NPTF threads offer the best potential for leak-free taper thread assemblies. Pre-applied sealant or adhesive should be used to compensate for any variations in the condition of the mating threads and the assembly process.

-

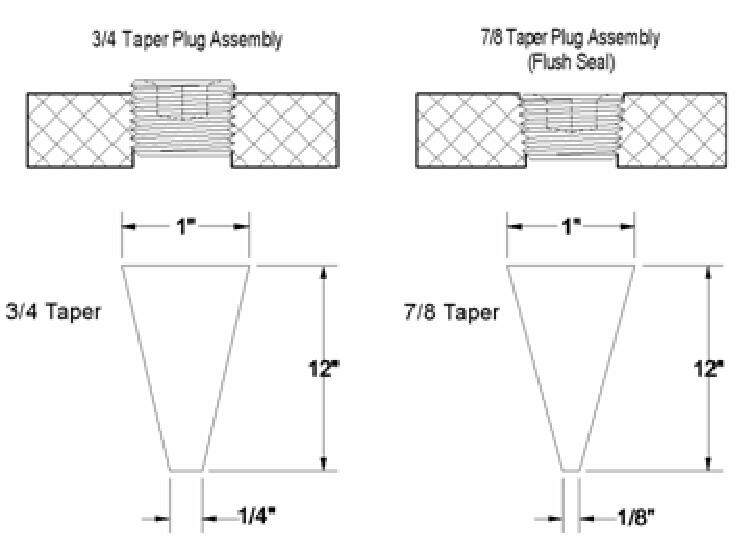

What are 3/4 and 7/8 Taper Thread Plugs?

"3/4" Taper" describes the diametrical taper of 3/4" per 12" of length of standard tapered pipe plug threads.

3/4 Taper is applicable to SAE, ASME/ANSI, DIN, British, and Japanese Standard tapered pipe plug threads.

"7/8 Taper" describes the diametrical taper of 7/8" per 12" of length of tapered flush seal PTF - 7/8 pipe plug threads.

-

What gages are needed to gauge a 3/4 taper thread pipe plug?

To correctly gauge a 3/4 taper thread pipe plug, two gages are required: an L1 Gage,which verifies the "bottom" size/threads; and an L2 Gage, which verifies the top size/threads.

-

What gages are needed to gauge a 7/8 taper thread pipe plug?

To correctly gauge a 7/8 taper thread pipe plug, two gages are required: an F2 Gage,which verifies the "bottom" size/threads; and an F1 Gage, which verifies the top size/threads.

-

Can "NPT" gages be used to gauge "NPTF" (Seaway) pipe plugs?

No. Use of "NPT" gages to gauge "NPTF" (Seaway) pipe plugs may erroneously indicate an out-of-spec part.

-

Why does an "inch" pipe plug not measure as the size indicates? (i.e. the threads of a 1/8" pipe plug do not measure 1/8")

Tapered pipe plugs are "sized" relative to the pipe or pipe fitting with which they are assembled; therefore, an "inch" pipe plug measures larger than the designated size. Often these pipe plug sizes are identified as "IPS" (Iron Pipe Size).

-

What is the difference between "SAE Short Standard" (PTF) and "SAE Long Standard" (NPTF) pipe plugs?

A Short Standard pipe plug is one thread pitch shorter than a Long Standard pipe plug, and the one thread is always removed from the bottom of the plug.

-

What are Seaway's Standard Packaging Details?

- Pallet and cartons are sized to maximize use of transit cube and warehouse storage space while maintaining manageable gross weights per carton and per full pallet.

- Cartons are packed “full” (no head space) to minimize transit damage caused by handling and stacking/crushing. Seaway's custom size bulk pack carton (7" x 7" x 5.25") assures that no full carton exceeds 40 lbs.

- Half pallets are used when appropriate to minimize the environmental impact of the disposal of packaging material. Half pallets also help to maximize transit cube space and warehouse storage space.

Pack Detail: Full Pallet Half Pallet Maximum Dimensions 30x30x25", 762x762x635mm 30x15x25" 762x381x635mm Maximum Weight 2600 lbs, 1180 kgs 1305 lbs, 592 kgs Maximum Cubes 13 cu ft, .367 cu meters 6.51 cu ft, .1843 cu meters Maximum Cartons/Layer

Maximum Cartons/Pallet16

648

32